Wetblast FLEX™: Skid-Mounted, All-in-One,

One Piece of Equipment for All of Your Blasting

Jobs—Wet and Dry

You take on many different types of jobs. You could be blasting in a populated area that requires wetblasting because dust suppression is a must, or blasting in an open area where you need the benefits of dry blasting for maximum productivity. You have to be ready for either one. But managing multiple pieces of specialized equipment costs you money and valuable storage space—not to mention that one of your systems will always be sitting idle and not making you money. Clemco’s Wetblast FLEX is ready for any job, wet or dry blast, ensuring your equipment is always in the field keeping your crew productive and your business profitable.

Graveyard Carz Wetblast FLEX Demo

[arve url=”https://vimeo.com/752148474″ mode=”lazyload” thumbnail=”24216″ title=”Graveyard Carz Wetblast FLEX” /]

High-Performance Wetblast Capabilities

Take on any wetblast job:

- Water and media mix before entering the blast nozzle, which helps:

- Maintain high media exit velocity, ensuring efficient blasting and desired surface finish.

- Fully saturate media with water, improving dust suppression for visibility and regulatory compliance.

- Ensure thorough wash down of blast surface for a contaminant-free finish.

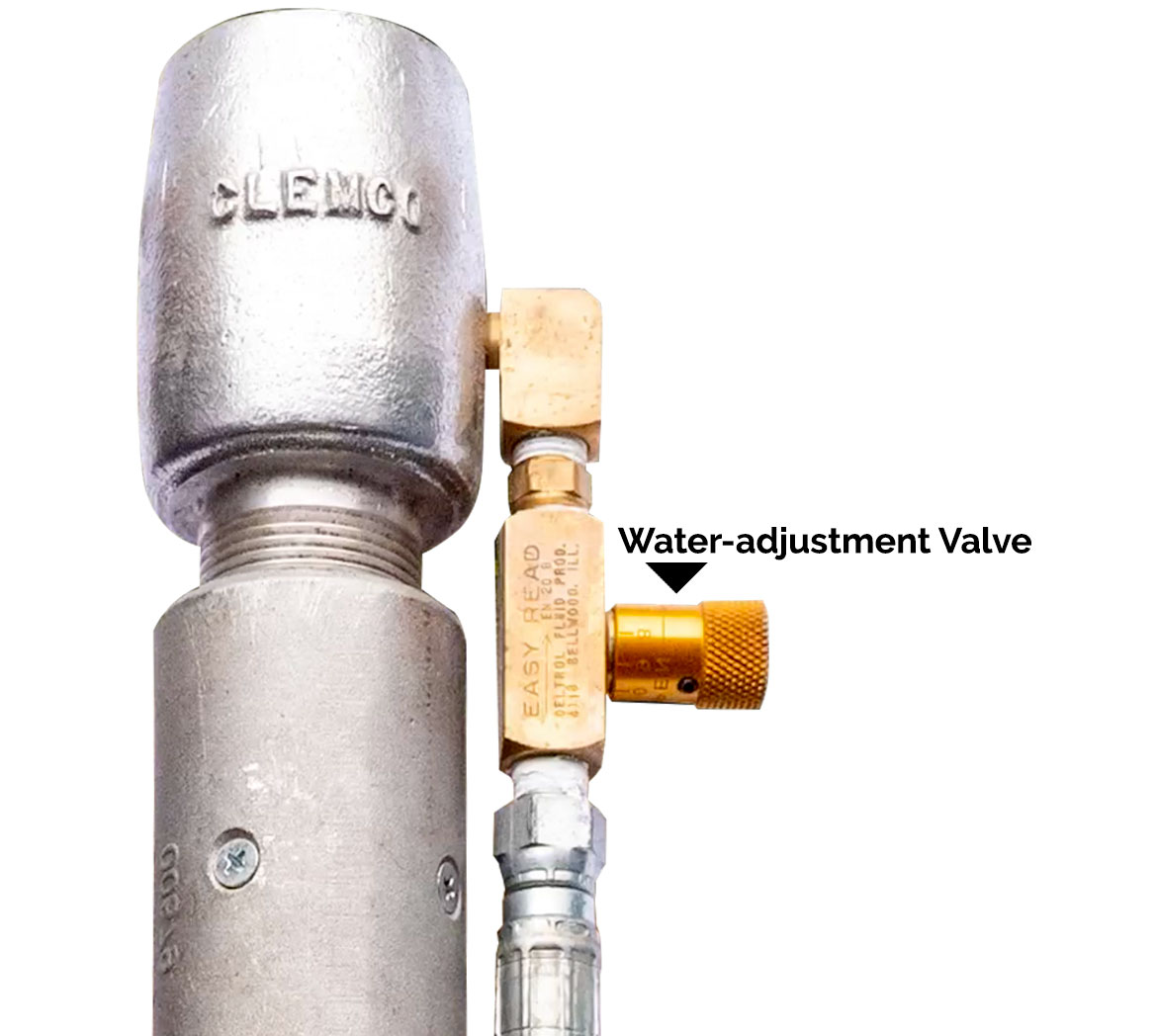

- The water injector assembly has precise water-adjustment controls for fine-tuning water flow into the blast stream. The assembly can be installed at two locations:

- Before the Blast Nozzle – Places water-adjustment controls at an operator’s fingertips for immediate adjustments to water-media mix while blasting, or for switching between wet and dry blasting.

- Base of the Metering Valve – Best location for reducing operator fatigue during long shifts. Operators do not need to hold the weight of the injector assembly.

Compliance

Allows you to comply with environmental safety regulations and safeguard your operators from exposure to hazardous dust:

- Suppresses dust generated during abrasive blasting, reducing operator, co-worker, and bystander exposure to hazardous dust.

- Helps satisfy urban dust-abatement requirements when blasting in metropolitan areas.

- Decreases dust-containment and cleanup costs, saving you time and expense.

Easy to Use

Simple controls, operation, and setup. If you’ve dry-abrasive blasted, you can wet or dry blast with a Wetblast FLEX:

- Simple setup:

- A single air connection controls all pneumatic functions.

- Connect to a pressurized, municipal water source such as an outdoor spigot.

- If a pressurized water source is unavailable, use the 120-gallon water tank and water pump that come standard with the Wetblast FLEX.

- Simple Controls:

- Precision water-adjustment valve allow operators to dial in the exact amount of water needed to suppress dust and produce the desired surface finish.

- Dry blast or wet blast by simply opening or closing the water valve.

- Turn on or off media flow with the flick of a switch for shifting between blasting and wash down.

Two Systems

Flex Base Unit

- Includes:

- Steel-framed, skid-mounted blast systems

- 6-cuft blast machine with remote controls

- 120-gallon water storage tank with water pump

Flex Package

- Includes:

- Everything listed above in a Base Unit

- A PPE and Blast Machine Accessory Package

Videos

Wetblast FLEX: Setup Guide

[arve url=”https://vimeo.com/405864872″ mode=”lazyload-lightbox” thumbnail=”23607″ title=”Wetblast FLEX: Setup Guide” /]

Midwest Miltary WetBlast Flex Demo

[arve url=”https://vimeo.com/719147258″ mode=”lazyload-lightbox” thumbnail=”23607″ title=”Midwest Miltary WetBlast Flex Demo” /]

Wetblasting also is known as wet abrasive blasting, wet blasting, vapor blasting, slurry blasting, dustless blasting, and wet sandblasting. However, sand should never be used when wet or dry abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.