The demand for high volume dry abrasive blasting of parts, components and complex pieces of equipment continues to grow as manufacturers and suppliers face ever higher production expectations from their customers. The ability to deliver large quantities of treated parts with consistently high quality requires flexible solutions that automate the blast process, minimize operator involvement, maximize blast coverage and keep the equipment running without unscheduled maintenance.

Clemco tumble cabinets are designed with a wide range of offerings and sizes to meet the applications for many different production processes and layouts. Our three categories of Tumble cabinets include the following.

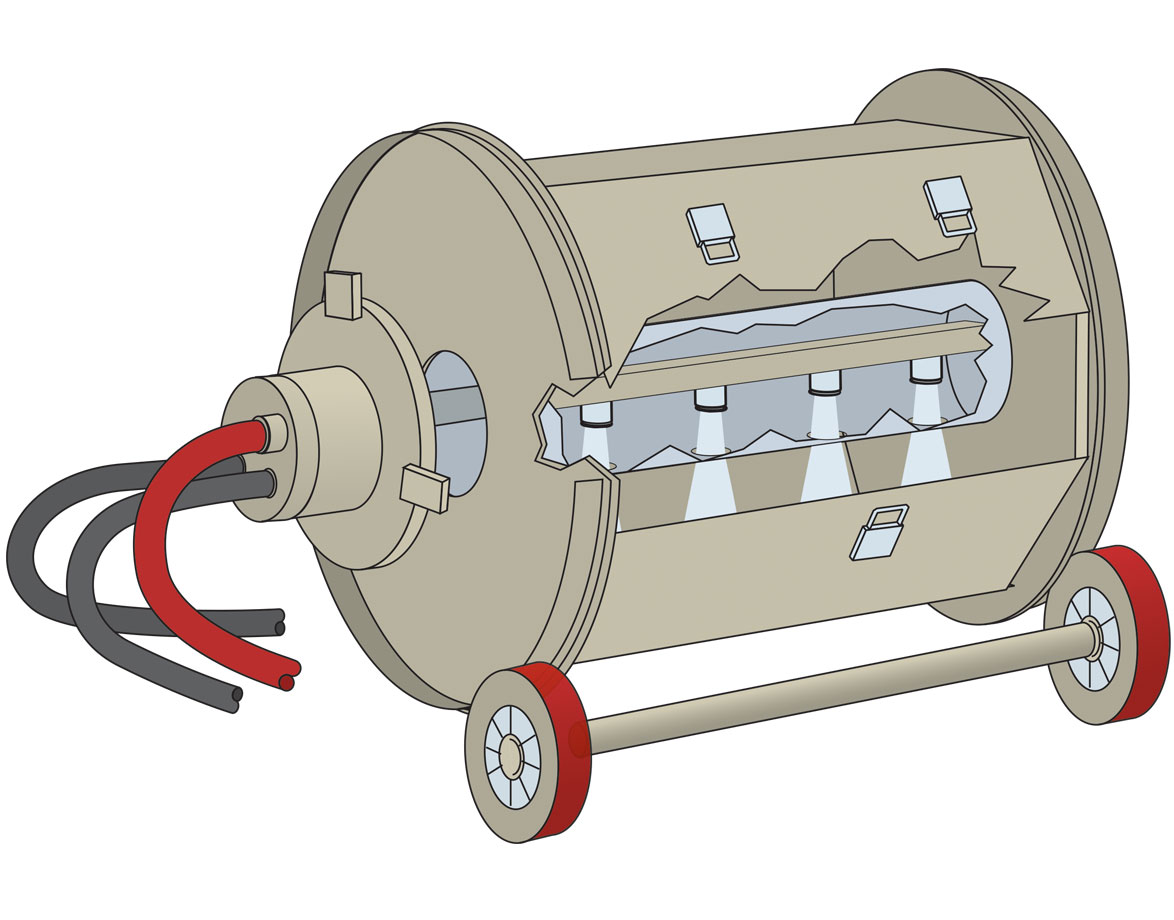

Tumble Barrel

- Our medium duty cabinet can still handle larger parts such as castings or valve bodies. Load limit is from 1cf – 3cf of space, with a weight capacity of 100 lb. – 300 lbs.

- All barrel models utilize reverse pulse dust collectors and reclaims for high performance media reclamation and cleaning.

Tumble Basket

- The smallest of our tumble cabinets, these handle 2 gallons to 4 gallons of capacity.

- The 4-gallon tumble basket, and the BNP-160, utilize reverse pulse cleaning. The DCM-161 uses a dust bag for dust collection and is a more economical offering.

Tumble Belt

- These provide the heaviest duty of our tumble cabinets and are designed to deliver high production over long periods of time. They offer large part capacities ranging from 2.5cf – 7cf of load room weighing 250 – 800 lbs. simultaneously.

- All belt models use reverse pulse dust collectors and reclaims for high performance media reclamation and cleaning.

Clemco responds to these challenges with superior tumble blast cabinets geared to meet the specific needs of customers in the aerospace, power generation, oil & gas, firearms, medical, automotive, food service and other industries. Our line of Belt, Barrel and Basket tumble cabinets deliver the productivity, performance and versatility needed by today’s customers in a wide range of capacity options with these benefits:

Productivity:

- Hands-free blast processing, which enables the operator to work on other tasks.

- Reduced operator involvement means less risk of operator fatigue or injury and no repetitive movement issues.

- Easy access to routine maintenance components reduces equipment downtime.

Performance:

- Consistent and repeatable blast process resulting in parts with the same finish. This takes hand operator variables out of the process, which can result in varying finishes.

- Automated movement of parts for consistent blast coverage over entire part. This eliminates the need for operator involvement to achieve 100% coverage while also enabling the finishing of geometrically complex part exteriors.

- High performance reclaim and dust collectors provide proper media reclamation and cleaning for consistent part finishes over time, resulting in limited parts rework and scrap.

Versatility:

- Simultaneous processing of a wide range of parts and applications in the same batches, ranging from a handful of screws up to hundreds of pounds of castings at one time. This valuable flexibility saves upfront cost, floor space, and time learning multiple pieces of equipment and maintaining them.

- Intuitive controls provide ease of operator use.

- Safety interlocks interrupt blasting if cabinet doors are opened to ensure the safety of operator and other team members.

Engineered Solutions

We will work directly with you to develop customized solutions to your specific abrasive blasting and cabinet needs and strengthen the overall performance and efficiency of your production operations. Want to learn more?

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.