Metering Valves | Remote Controls

Pneumatic

-

Ideal for Complex Blasting Setups: Designed for pressure-release and pressure-hold systems, especially where multiple hose lengths or elevated work (like scaffolding) are involved.

Abrasive Cutoff Capability: Allows operators to stop media flow during blasting, preventing hose slugging and enabling quick clearing between uses.

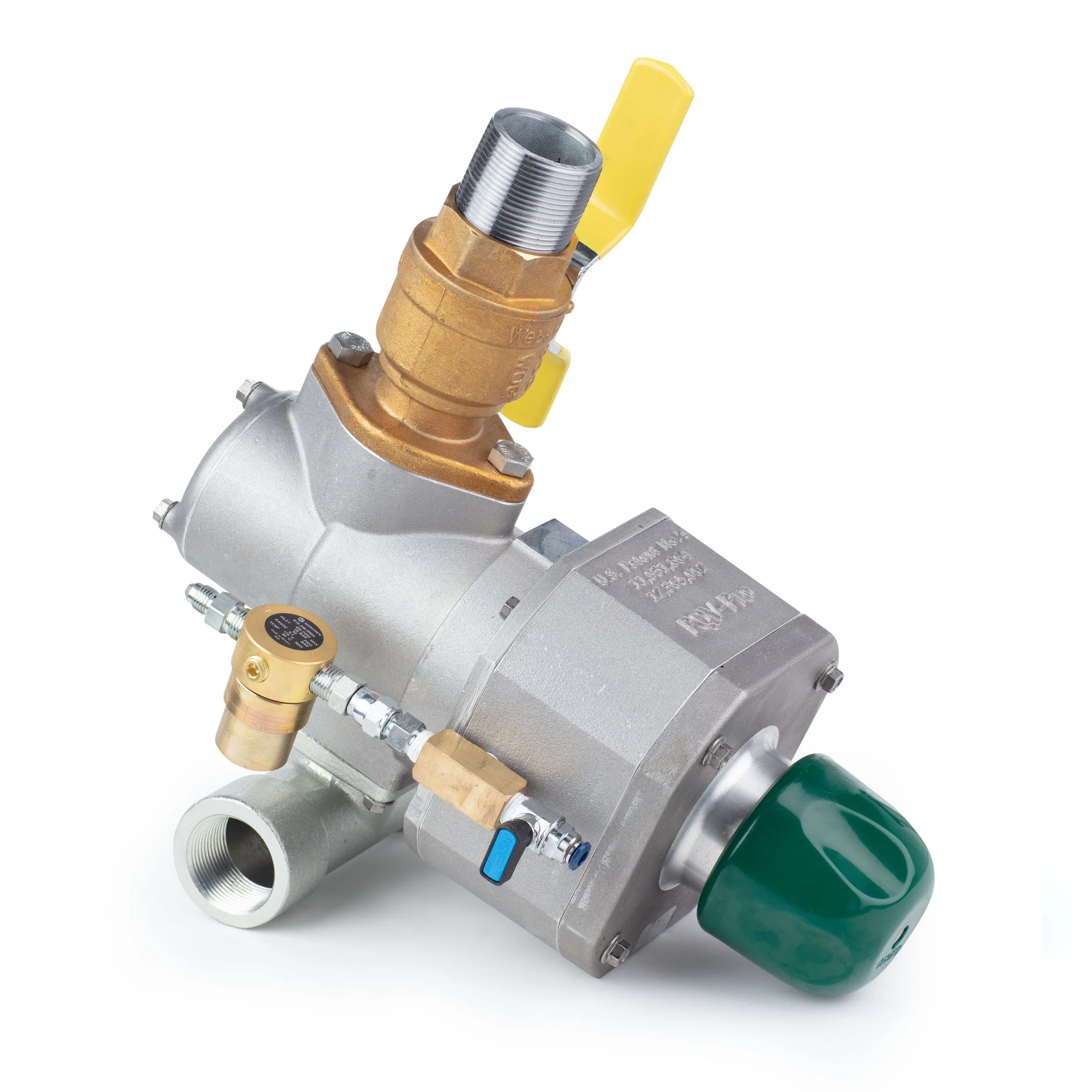

PQV-Pro Valve: Versatile for both pressure-hold and pressure-release systems; supports all common media, offers adjustable flow during operation, and features simplified maintenance with 60% fewer wear parts.

Auto Quantum Valve (AQV): Compatible with all common media; used in pressure-release systems with 3-cuft and larger machines.

Sentinel Valve: Tailored for fine-mesh media, often used in pressure-release blast cabinets for precision applications.

Manual

-

Designed for Long-Duration, Ground-Level Blasting: Ideal when blasting for extended periods with short blast hose runs on the ground.

MQV-Pro (Manual Quantum Valve): Compatible with all common media; fits 2-cuft and larger blast machines.

FSV & MSV (Flat and Manual Sand Valves): FSV is for larger machines using expendable mineral or slag media; MSV fits ½- and 1-cuft machines with similar media.

LPV (Lo-Pot Valve): Specially designed for 6-cuft Lo-Pot machines, its compact form fits the low-clearance configuration.

LMV (Lightweight Media Valve): Optimized for soft abrasives like soda, glass bead, and agricultural media in Soft King and Pool Pal machines.

Remote Controls

-

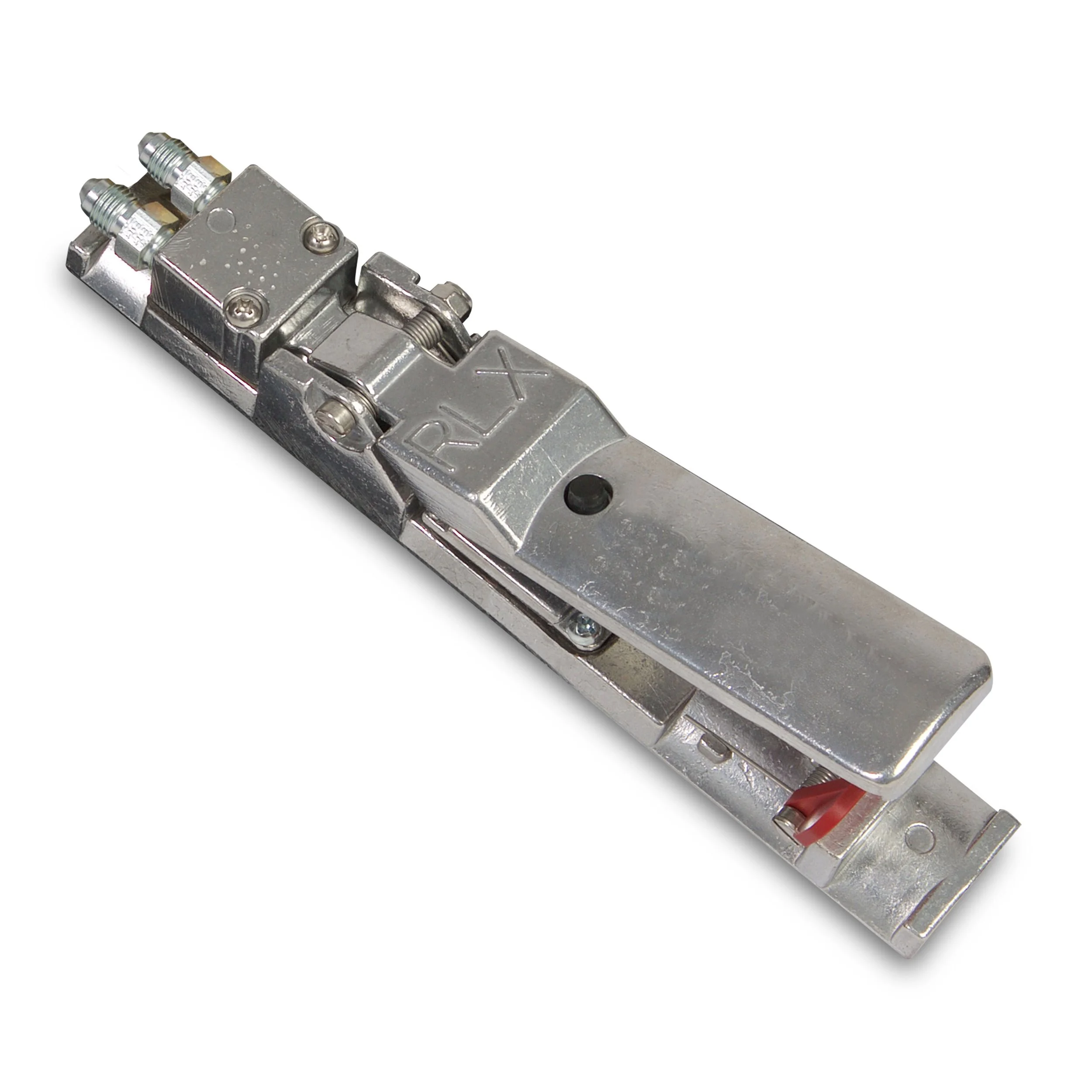

Operator-Controlled Blasting: Allows operators to start and stop blasting with fingertip controls near the nozzle for enhanced convenience and safety.

Fail-to-Safe Design: Automatically halts blasting if the operator drops or loses grip on the control handle, prioritizing jobsite safety.

OSHA-Compliant: Meets regulatory requirements that mandate remote control operation for all abrasive blasting machines.

Pneumatic Option: Ideal for setups with up to 100 ft of blast hose; reliable for standard temperature environments.

Electric Option: Designed for longer hose runs (over 100 ft) or cold-weather conditions, functioning effectively up to 500 ft with appropriate control cord.

Proven Performance. Rugged Reliability.

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941 • Generations of Excellence Transforming Our World, Worldwide since 1941 • Generations of Excellence Transforming Our World, Worldwide since 1941 •