Spare Parts & Accessories

Hoses

-

Application-Driven Hose Selection: The right blast hose depends on distance, environment, and mobility needs—from short whip hose runs near the blast machine to 100+ ft industrial setups.

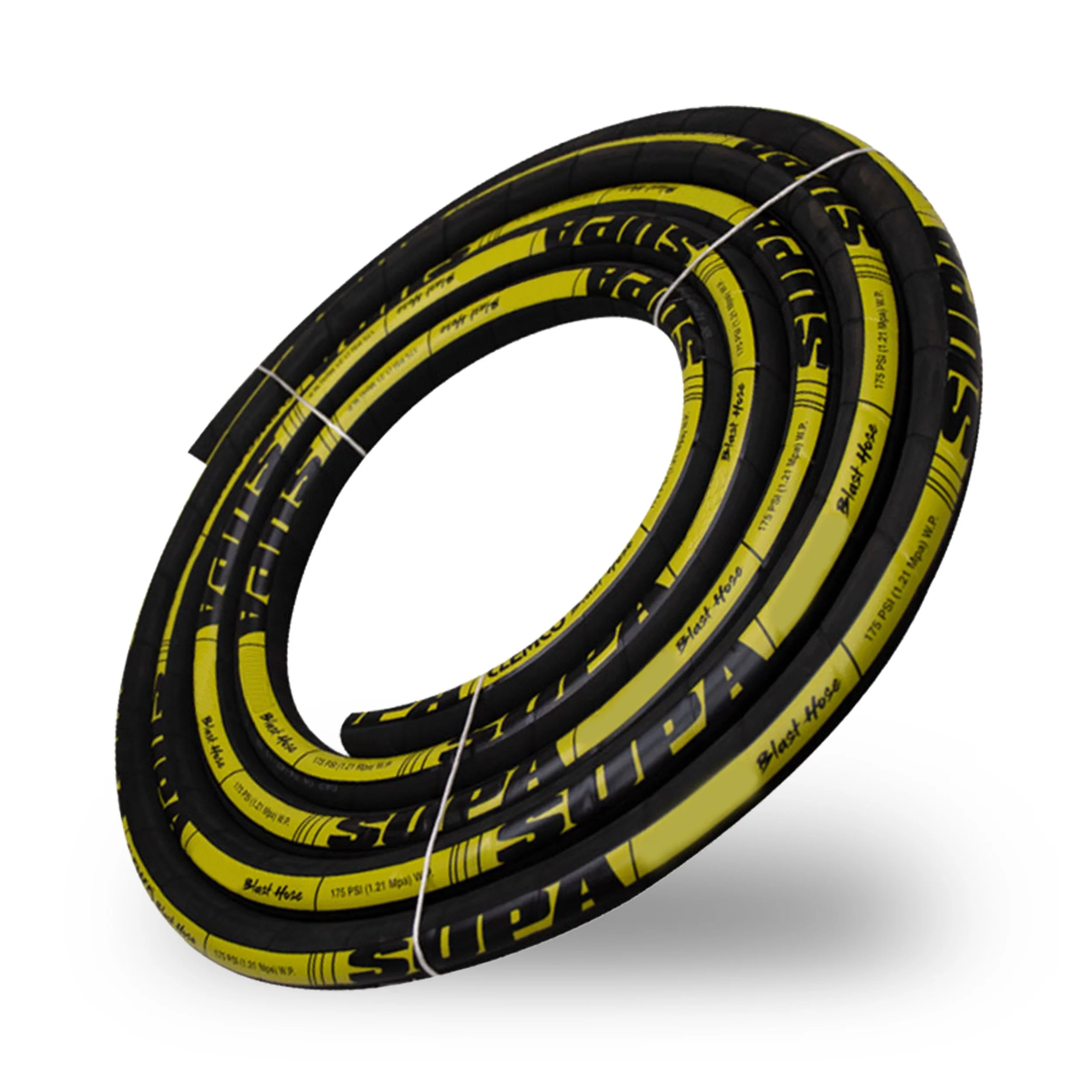

Supa Blast Hose: Lightweight and highly flexible, ideal for portable field use or as an operator whip hose to reduce fatigue during short-range blasting.

2-Braid Blast Hose: Offers more durability than Supa with a thicker outer wall, built for industrial environments where moderate abrasion or scuffing is expected.

4-Ply Blast Hose: Clemco’s toughest option with the thickest outer wall—engineered for long hose runs, heavy-duty use, and resistance to scuffing and occasional light vehicle traffic.

Flexibility Meets Durability: Each hose balances strength and maneuverability, ensuring safe, productive blasting whether on a jobsite, in a factory, or across rugged terrain.

Nozzles

-

OEM Quality for Optimized Performance: Clemco’s nozzles and holders are precisely designed to integrate with Clemco blasting systems, minimizing downtime and ensuring efficient use of media and compressed air.

Wide Range of Nozzle Types: Includes Tungsten, Silicon and Boron long and short venturi nozzles for varied blast patterns, straight-barrel nozzles for precision work, and side-angle nozzles for hard-to-reach areas—allowing users to match the nozzle to the task.

Lightweight and Durable Materials: Nozzle holders are made from fiber-reinforced nylon or aluminum to reduce operator fatigue. Nylon versions include integrated lock-springs for added safety and convenience.

Quick Change and Safety-First Design: Holders feature quick quarter-turn connections and locking mechanisms to prevent accidental disconnection, and support multiple thread types including fine thread, contractor thread, and flanged styles.

Maintains Hose Integrity and System Reliability: Clemco nozzle holders secure to the hose’s outer wall without damaging the inner tube, ensuring airtight connections and safe, consistent operation.

Couplings

-

Secure, Leak-Free Connections: Couplings ensure tight seals between blast hoses and machines, preventing air and media leaks that could compromise safety or performance.

Nylon Couplings: Lightweight and fatigue-reducing, with a built-in lock spring that eliminates the need for safety pins—ideal for ease of use and operator efficiency.

Aluminum Couplings: Also lightweight and well-suited for scenarios where operators must support vertical hose sections, such as on scaffolding or elevated platforms.

Brass Couplings: The most durable option for high-abuse environments with frequent hose dragging—heavier, but designed for rugged industrial use.

Safety Cable Integration: Available for all common hose sizes (½" to 4" OD), Clemco safety cables help prevent injuries by restraining whipping hoses in the event of coupling failure.

Pipe Tools

-

360° Rotating Blast Head: Features dual nozzles mounted on a pneumatically powered rotating head to deliver uniform blasting across the full interior pipe surface—eliminating the need to rotate the pipe itself.

High-Production Efficiency: Significantly speeds up pipe cleaning compared to manual blasting, ensuring consistent surface profiles for reliable coating adhesion and jobsite productivity.

Two Size Models Available:

Pipe Pro XL 1631: For pipes with 16″–31″ inner diameter

Pipe Pro XL 1660: For pipes with 16″–60″ inner diameter.

Simple Integration & Operation: Quickly attaches to existing blast hose; head speed can be fine-tuned by air valve adjustment; centering carriage with urethane wheels ensures proper alignment inside the pipe.

Compact, Safe & Cost‑Effective Tool: Compact design is easy to transport and store; eliminates need for mechanical pipe rotation, keeps operators out of confined space exposure—enhancing safety while reducing accessory costs and setup time.

Power Gun

-

Ultra-Portable Suction Blaster: Lightweight, handheld design makes it ideal for confined or awkward spaces—such as scaffolds, ships, staircases, or elevated areas—without needing a full-scale pressure blast machine.

Near-Pressure System Performance: Despite being a suction-based tool, it delivers blasting capability comparable to a 1-cuft pressure system using commonly available abrasives (12‑mesh and finer), without the complexity or setup time of pressure vessels.

Fast and Simple Operation: Set up by connecting compressed air and inserting the suction lance into a media bag or optional hopper; blasting begins with a trigger pull. The H₂O model adds water for optional wet blasting, wash-down, or dry blow-off using fingertip controls.

Low Air Requirements: Consumes between ~40 CFM to 120 CFM depending on pressure, making it suitable for use with smaller compressors or limited-air conditions.

Dust Suppression Option (H₂O Model): The PowerGun H₂O enables wet blasting to suppress dust in urban or regulated environments, improving compliance, visibility, cleanup, and operator safety.

Suction Gun

-

Compact & Portable Touch‑Up Blasting Tool: The SG‑300 is a handheld suction-style blast system that delivers performance comparable to a ½‑cuft pressure blast machine—ideal for quick jobs or confined areas.

Low Air Consumption: Works with limited air supply, consuming as little as 12–40 CFM depending on pressure and nozzle choice, making it suitable for small compressors or remote locations.

Easy Setup & Operation: Attach air and media hoses, fill the 1-cuft hopper or insert the suction lance into a media bag, then squeeze the trigger to blast—with metered, consistent abrasive flow.

Versatile Applications: Works with most common abrasives (16-mesh and finer); ideal for glass or stone engraving, light paint stripping, touch-up work, or cleaning delicate surfaces in workshops, farms, or rental fleets.

OSHA‑Compliant & Safe: Equipped with a trigger-control mechanism compliant with OSHA blasting regulations (1910.244(b)), includes a removable screen to filter media, and supports use of non‑silica abrasives only.

Proven Performance. Rugged Reliability.

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941

•

Generations of Excellence Transforming Our World, Worldwide since 1941 • Generations of Excellence Transforming Our World, Worldwide since 1941 • Generations of Excellence Transforming Our World, Worldwide since 1941 •