Avoid Unplanned Downtime and Drops to Your Productivity

Quality matters. The quality of your work, of your blast machines, and of their accessories and spares. Clemco manufactures OEM blast machine accessories and spares, designed to the specifications of your Clemco blast machine. Media screens, blast machine covers, coalescent filters, and moisture separators help prevent unplanned downtime and hits to your productivity caused by moisture or debris entering media, and Beacon Blast Lights help maintain operator productivity by increasing visibility in low-light conditions. Protect the safety of your operators, protect your reputation for quality work, by using these Clemco OEM accessories and spares:

- Blast Machine Screens and Covers – Prevent media blockages caused by moisture or debris.

- Coalescent Filters and Moisture Separators – Keep media dry and flowing by preventing moisture from entering media.

- Beacon Blast Light – Increases operator productivity by increasing visibility of the blast surface in low-light conditions.

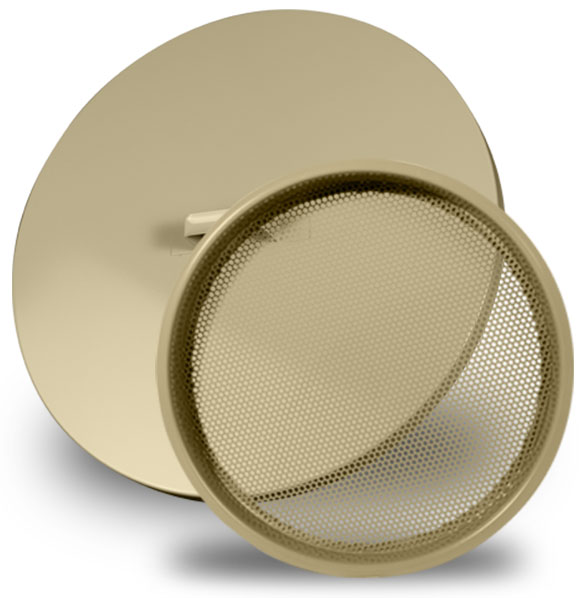

Blast Machine Screens and Covers – Prevent Media Blockages

Your blast machines need clean, dry media to operate productively and to prevent wear on internal components. Moisture or debris that gets into media can create blockages that lead to downtime and damage to your blast machines. Keep your pots running smoothly by screening out debris and prevent media from clumping by keeping moisture out with Clemco OEM blast machine screens and covers:

- Screens – Prevent large debris that is mixed in with media from getting inside your blast machine and creating blockages. Sized to fit Clemco blast machines ranging from 1/2 to 20 cuft.

- Blast Machine Covers – Keep moisture from unexpected weather changes, rain, or snow from entering your blast machine and creating media blockages. Sized to fit Clemco blast machines ranging from 1/2 to 20 cuft.

Moisture Separators and Coalescent Filters – Keep Media Dry and Flowing

Moisture in compressed air lines can cause inconsistent media flow or even completely stop the flow, which leads to downtime because operators need to clear the blockages before they can get back to blasting. You need moisture free air to keep your operators focused on the job they are there to do—abrasive blasting. That’s why Clemco offers moisture separators and coalescent filters to fit the requirements of your blast machines and applications:

- Coalescent Filters – Remove water from compressed air supplies to prevent clumped media from creating blockages. Clemco offers two types of coalescent filters:

- High Volume – This portable, freestanding coalescent filter removes water from the compressed air supply of multiple blast machines. It can handle up to 800 CFM.

- Inline – The inline coalescent filter is plumbed directly into a single blast machine’s inlet-supply air plumbing. It can handle up to 200 CFM.

- Moisture Separators

- Inline – These inline moisture separators are plumbed directly into a blast machine’s inlet supply before its coalescent filter. This placement helps a moisture separator remove the majority of moisture so that the coalescent filter does not overload. Different sized inline moisture separators are offered for blast machines with plumbing ranging from 1/2” to to 2”.

Beacon Blast Light – Increases Productivity by Increasing Visibility

Improve the visibility of the blast surface for operators blasting in poorly lit areas or without natural light with a Beacon Blast Light:

- Powerful 860-lumen LED light provides 6000K color temperature, similar to daylight on a sunny day.

- Light beam capable of penetrating up to 280 ft.

- Compact, lightweight, and rugged. Designed for demanding abrasive blasting applications.

- Available in 12V DC and 120V AC.

Abrasive blasting (formerly known as sandblasting) also is called grit blasting, bead blasting, media blasting, soda blasting, dry blasting, sponge blasting, shot blasting, and shot peening. However, sand should never be used when abrasive blasting because breathing abrasive containing crystalline (free) silica can lead to serious or fatal lung disease.